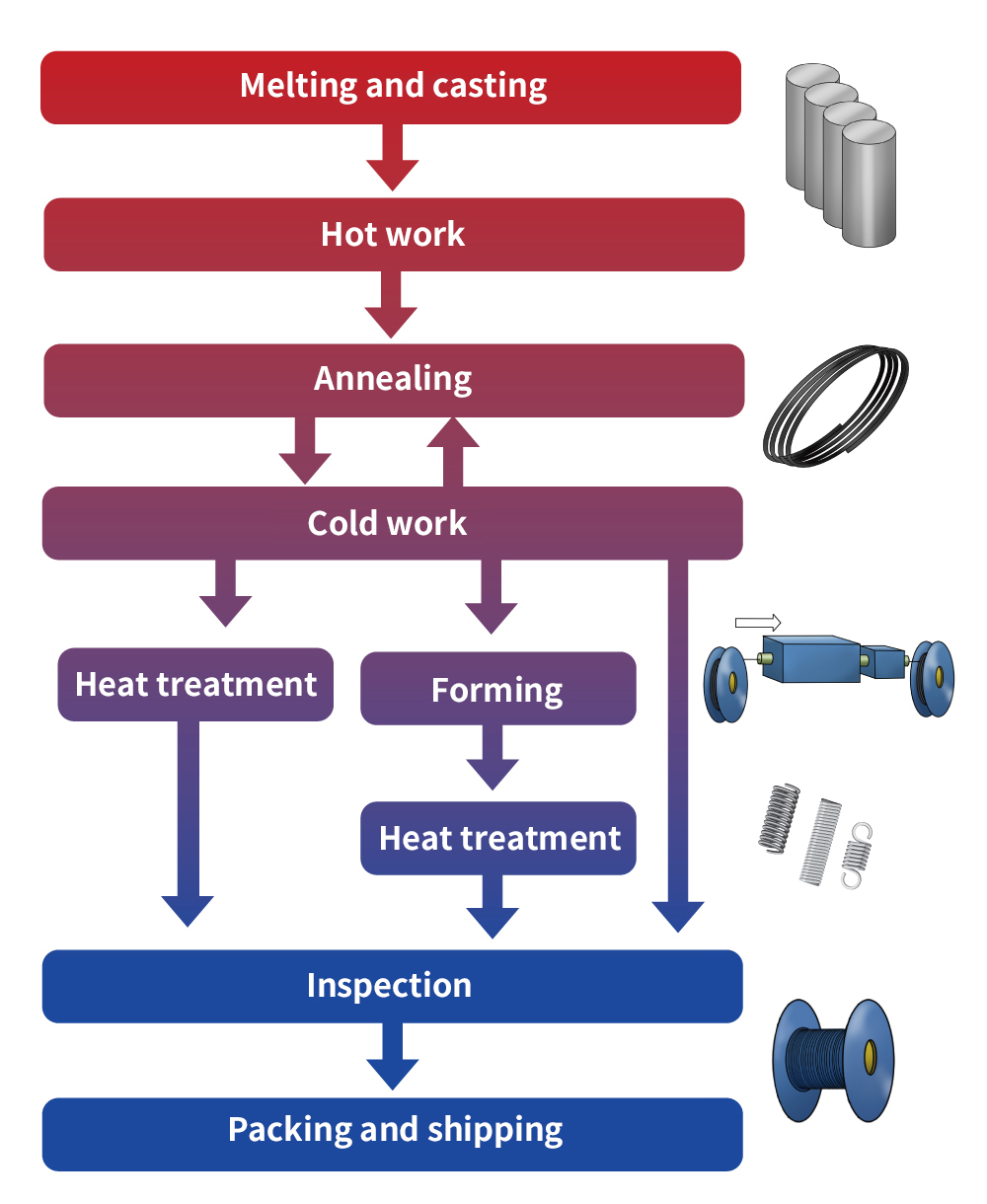

Manufacturing Process

Manufacturing Process

Our manufacturing process is specialized and optimized for Nickel alloys from melting to final products with a highly quality control system. High performance and highly reliable special metals such as shape memory alloys, electric resistance materials, thermocouple materials and heat-resistant materials for existing applications and new product developments are available. We can provide tailor-made products with fine-tuned support for your needs.

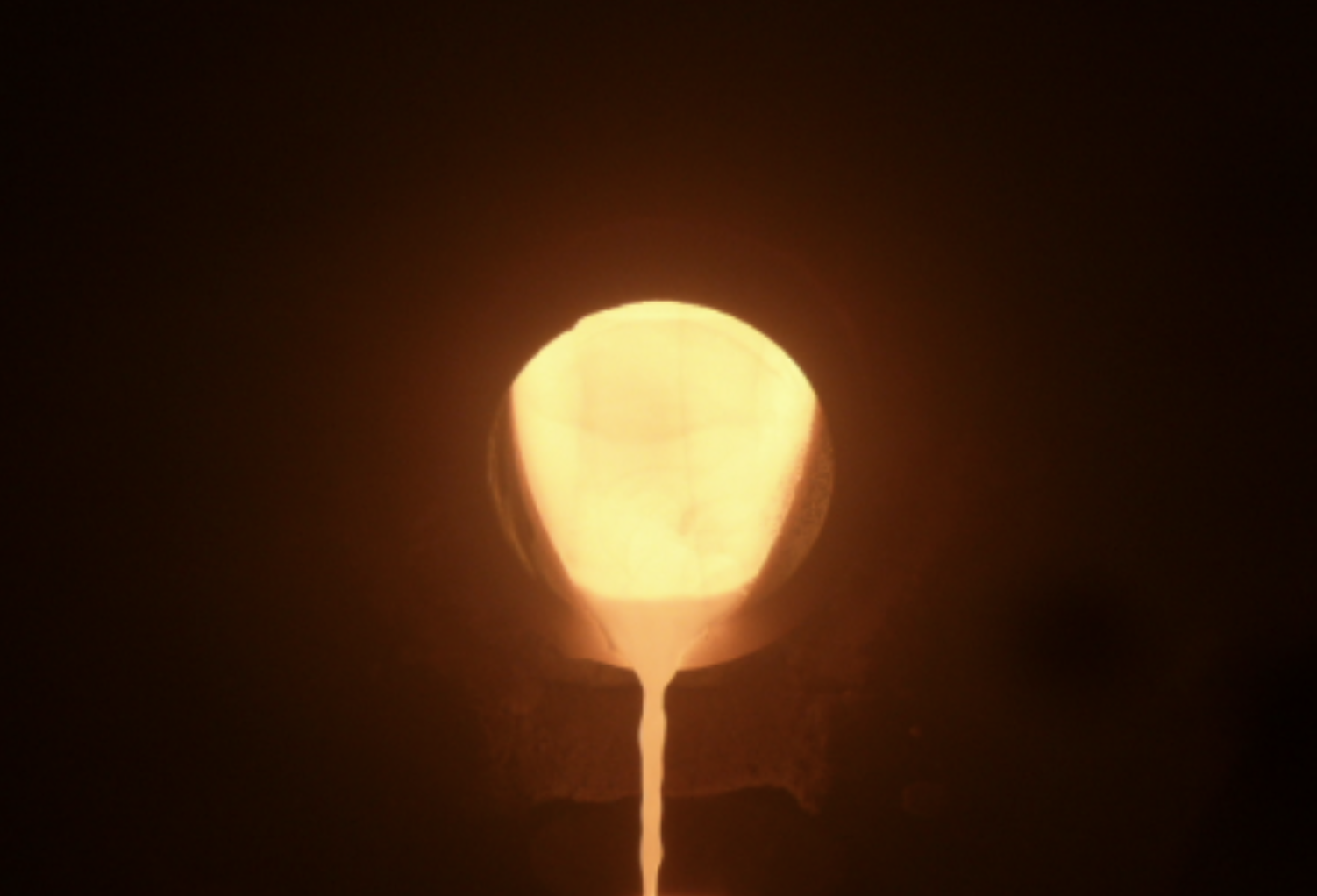

Melting & Casting

Ni alloy is melted and cast in a vacuum chamber due to avoid oxidation.

Vacuum Induction High Frequency Melting & Casting Furnace

Molten at casting

Hot rolling

The ingot is pre-heated and rolled down by hot reverse rolling and following hot tandem rolling.

Pre- heating furnace before hot rolling

Hot reverse rolling

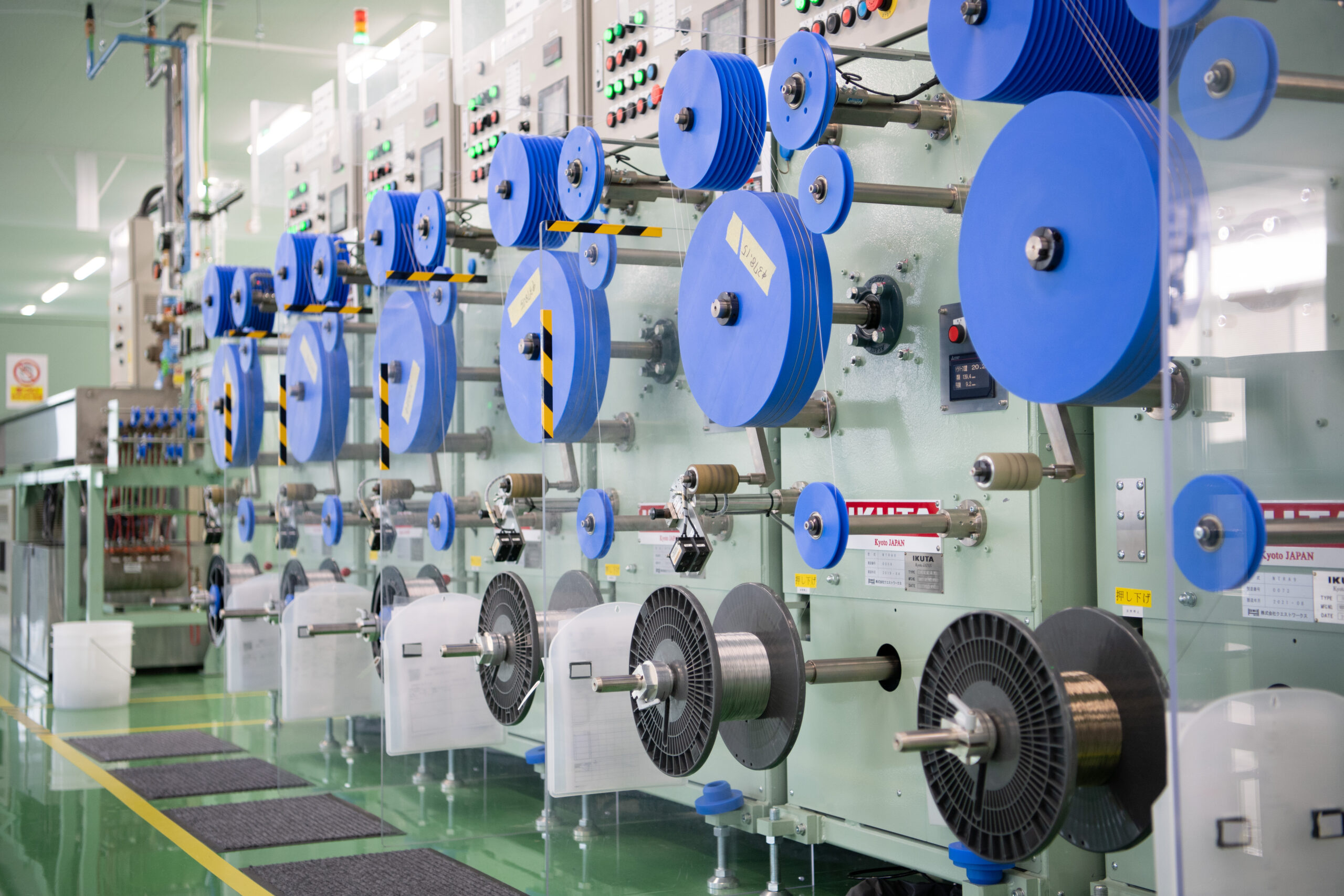

Cold work ( cold drawing or rolling)

Cold drawing or cold rolling is performed, and then appropriately annealed to remove working strain.

Cold drawing

Running furnace